Product Description

We are out of black consumable tables and you can only choose tables in regular MDF instead of black

Made to order with a delivery time of 2-4 weeks.

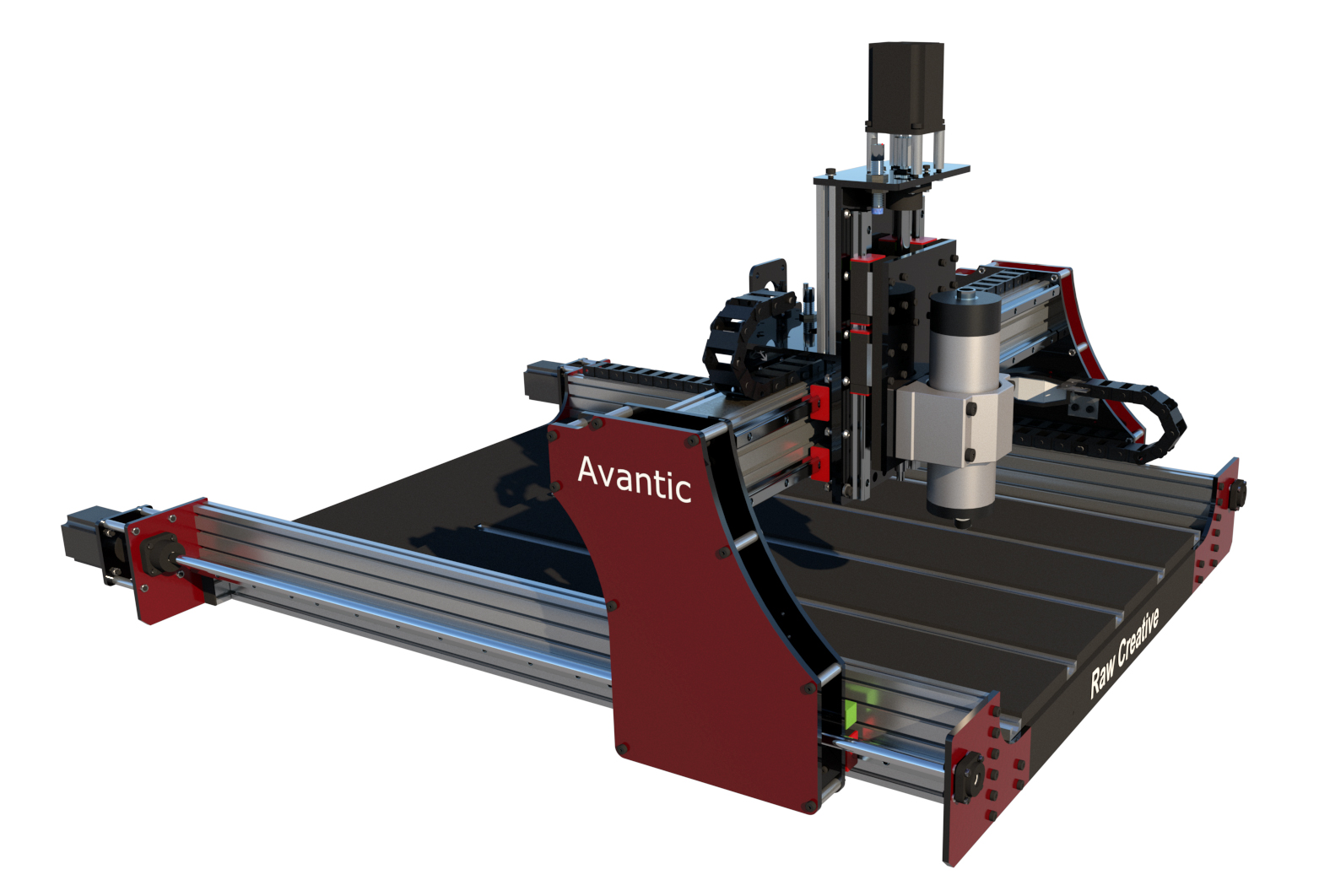

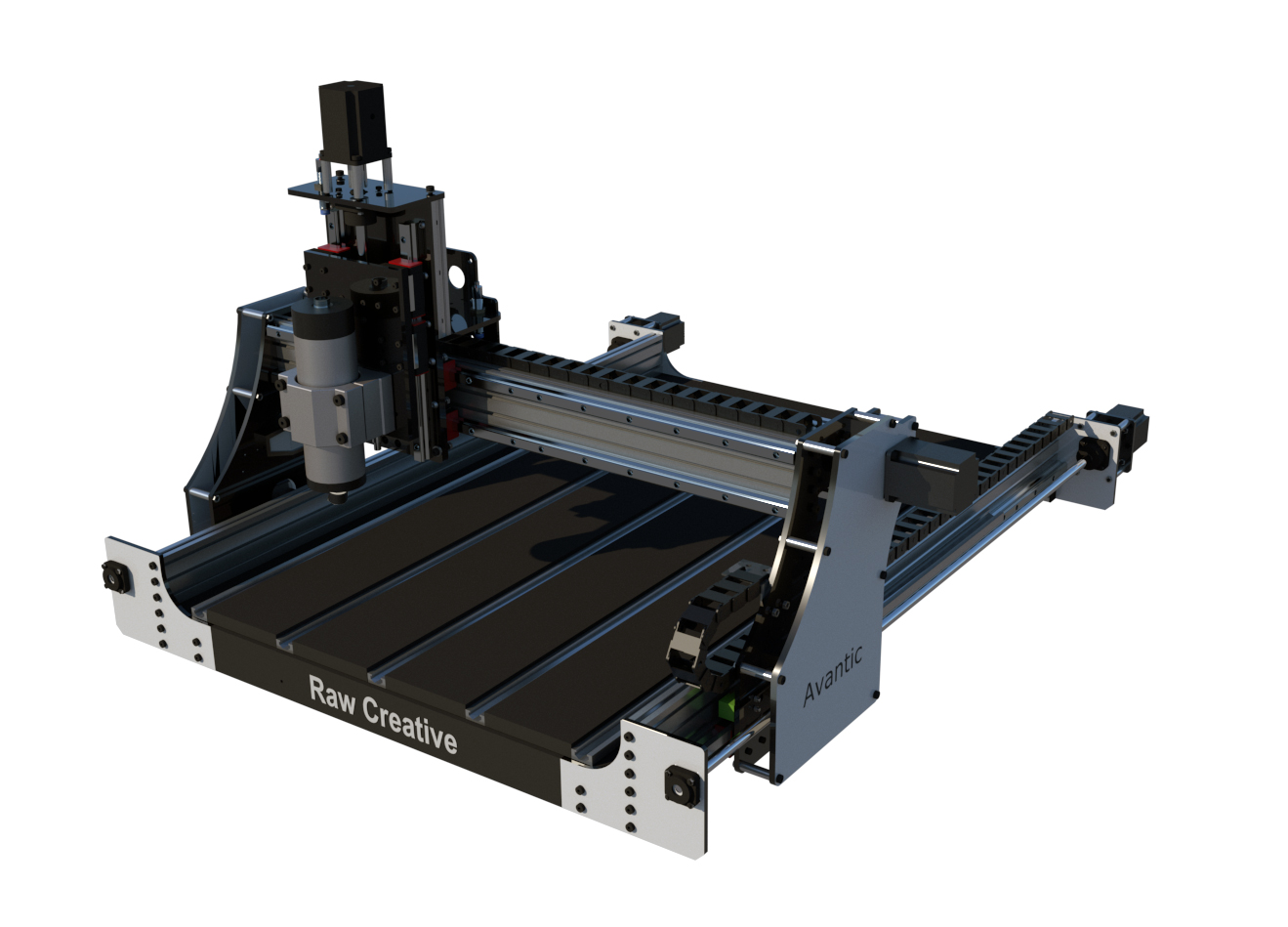

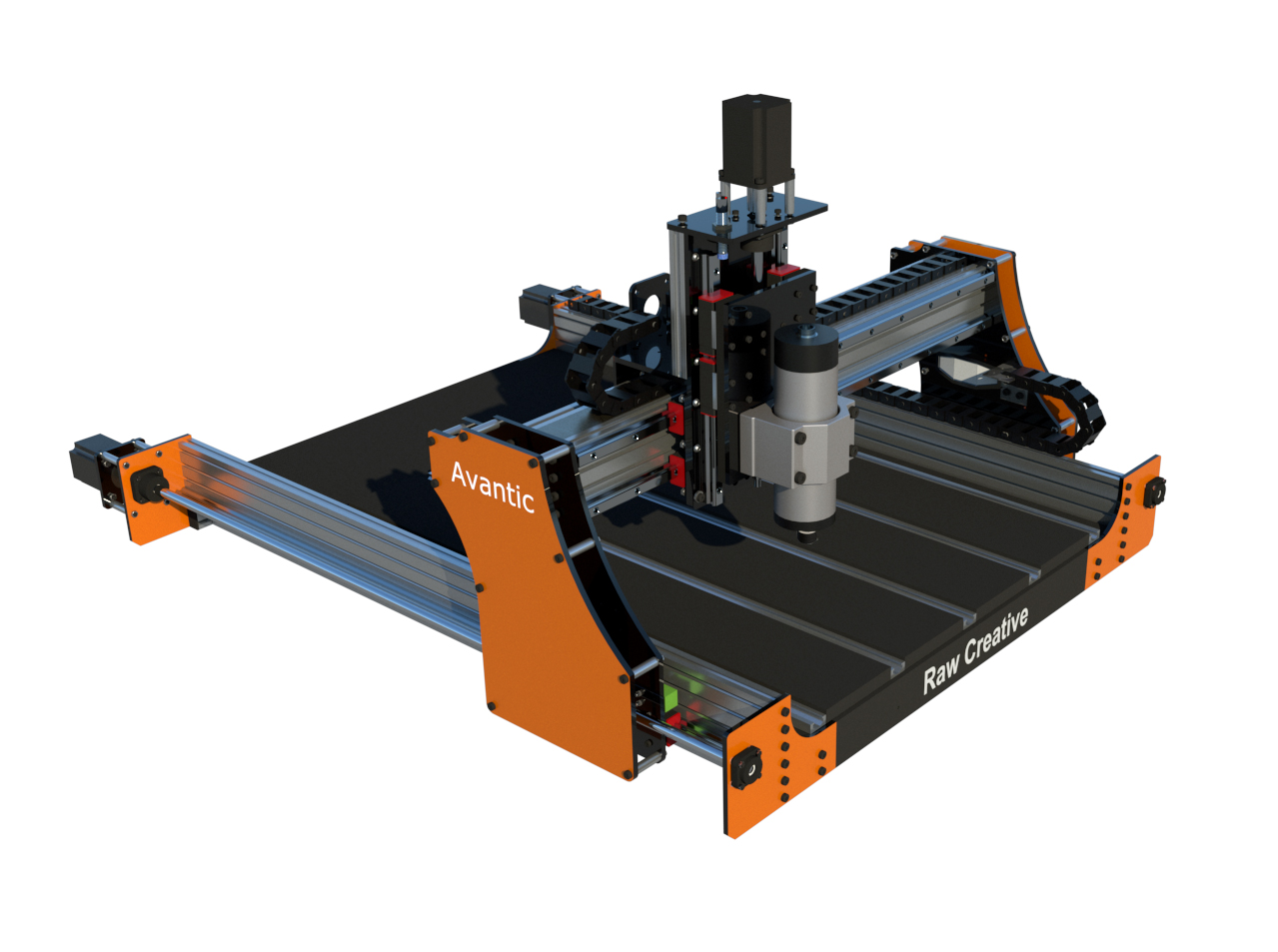

A CNC machine for professionals and hobbyists Ball screw version

Raw Avantic Creative Edition is probably the strongest “hobby” machine on the market, with thick steel plates and an aluminium frame. The machine can cut with extremely high precision and speed.

Choose a ball screw machine if you want an extremely accurate machine. Ball-screw machines are slower and can only be built up to 1×1 metres in size, but they offer precision suited to those who need extremely fine detail, for example in 3D carving.

Creative is built to a high standard with linear guides and industrial-grade electronics, and uses the same software as professional machines.

Note that this machine comes fully assembled, so you don’t have to put it together like with many others on the market.

15mm Linear Rails

Raw Creative runs on real linear rails. Linear rails give the machine the stability and rigidity that a true CNC machine requires. Other machines in the same price range use plastic wheels that are more suited to 3D printers and toys. Linear rails are expensive, but we have pushed the price down as far as possible because we believe they are the only sensible solution for a good machine.

There are 12 linear bearing blocks on the rails, each of which can be lubricated individually.

Waste board

When you order your Raw Creative machine, you can choose to add a complete spoilboard tailored to the machine’s design. The spoilboard consists of two layers: a sacrificial top surface and a base board that keeps the machine locked square at 90 degrees. The top layer (the wear surface) can be easily replaced as it wears.

If you want to build your own table, you can do that—see the video here:

https://youtu.be/ztYKh6xacE8?si=Cxs_SwPBbNNJnqMY

The image above shows a spoilboard in black, moisture-resistant MDF.

Stepper Motors

We have chosen to equip the machine with powerful 3-amp NEMA 23 stepper motors instead of the weaker NEMA 17 motors found in many other machines in this price range. The frame is made of aluminium and the plates of steel and HPL, yet the machine still maintains a relatively low weight thanks to its optimised design and structure.

The motors are strong enough that a fully grown adult could stand on the gantry while the machine is cutting.

📐 Size

Please note that this machine is only available in 1000×764 mm with a cutting area of (L) 720 × (W) 500 mm, and 1000×1100 mm with a cutting area of (L) 720 × (W) 720 mm. These are the only sizes we offer for ball-screw machines. The size is sufficient for most needs, and you can also cut longer parts by advancing the workpiece during cutting. If you need a larger machine, please take a look at our rack-and-pinion machines.

Spindle / Router

We’ve adapted the machine for different mounts so you can choose the cutting head you prefer. We include a 65 mm mount that fits a 1.5 kW spindle or the trim routers mentioned below.

You can use a standard trim router from, for example, Makita, Bosch or DeWalt. A spindle with a VFD needs to be wired/ connected. You can choose to have the machine delivered with a 1.5 kW spindle installed, but that option is more expensive.

You can find inexpensive trim routers on Amazon as an example (note: choose the standard round 65 mm body).

The Z-axis features both a ball screw and linear guides for maximum precision.

Calibration & Limit Switches

Raw Creative is equipped with inductive switches that are more reliable and contain no moving parts. We’ve ensured the machine has switches in every direction for emergency stop, calibration, and zeroing the coordinates.

This machine has a unique feature where you can “force” the machine to square itself to 90° at startup so it cuts perfect parts.

Thanks to the inductive switches for each motor, the machine can position all motors at the specified distance.

Precision

Precision is a balance between the user and the machine. It depends on how good your drawings are, the spindle, RPM, and how fast you cut. At a normal cutting speed of about 2,000–4,000 mm/min, the machine has the same accuracy as expensive industrial machines.

Repeatability: ±0.1–0.05 mm Backlash: ±0.1–0.05 mm

The machine is primarily built to cut wood, plastics and similar materials. You can cut aluminium, but it requires the right settings regardless of which machine you use

Software

The Raw Creative is built for the Mach3 control software but is fully compatible with any control software that drives 3 A NEMA 23 motors, such as Mach3/4, UCCNC, Arduino/GRBL, LinuxCNC, or others. You are free to switch to any system you like, but we recommend Mach3 and only provide support for it. If you switch the control software, you will also need to change the controller board to match the respective system, such as LinuxCNC, GRBL, or similar.

Mach3

Mach3 is the most used control software in the world, which means that there is more support and features for this software than any other. Mach3 looks outdated but we have updated it with our own UI to make it look more modern. The update is completely free for customers and instructions can be found here: Update Mach3, see image to the right.

UCCNC, Linux or other control software

Avantic is compatible with most control software but we only have settings for Mach3. If you have decent knowledge of control programs, it is easy to change control card and set the machine to any option.

To set up the machine

After your machine is delivered, it must be set up with control software to be able to run. You can also choose to include a computer when purchasing. The computer is then completely installed, but you need to purchase a monitor, mouse and keyboard.

We have a guide for this at the top of the page “Configure your machine” If you encounter obstacles or feel that you do not have time, we can do it for you. Send the computer to us while you wait for your machine. The computer should be version WINDOWS 7-10. The computer can be used and laptop or desktop. The computer does not need to have high performance as it will only control the machine. We recommend that you have a separate computer to control the machine.

What Is the Machine Made Of?

The frame is made of aluminum profiles, reinforced with steel tubes over the X-axis. The linear steel rails and rack on all axes serve as extra reinforcement of the profiles. The load-bearing plates are made of 6mm powder-coated steel while the colored plates are made of HPL.

Creative uses 4 motors instead of 3 so that all axes have their own motor for strength and pressure. Together with industrial electronics, the machine becomes a workhorse that is built to work with. Feel free to compare the construction and price of this machine with other “hobby” machines and you will immediately see that a Raw Creative is in a completely different class. Raw Creative is probably the most well-built and strongest CNC kit on the market.

💰 Price – Why You Get More for Your Money With Us

Our strength? We have been developing and manufacturing our own CNC machines for over 15 years and have developed Raw Creative ourselves – without any intermediaries. This means you pay for real performance, not for marketing or distribution.

We’re able to offer a competitive price because we:

✅ Laser-cut all metal components in-house

✅ Apply durable powder coating in our own facility

✅ Cut aluminum and steel profiles with digitally guided precision saws

✅ Purchase materials in large volumes to reduce costs

✅ Repackage and optimize part quantities so you avoid overbuying, incorrect orders, or high shipping fees

The result? A fully assembled, tested, and complete machine that delivers better value – and far less hassle – than building one from scratch.

What Can You Cut with a Raw Creative?

Softwood, hardwood, chipboard, MDF, plastic, aluminum, signage materials, 3D carvings, and engraving — all are possible with Raw Creative.

Please note that aluminum and other soft metals are generally more difficult to cut, no matter which machine you use. If your primary goal is to cut metal, a laser cutter or waterjet machine may be a better choice.

Specifications

- Color: Black, White, Concrete/Camo, Pink, Oxblood, Orange and Green.

- Material: Steel sheet, Composite and Aluminum reinforced with steel

- Consumer table: Replaceable with rails (optional)

- Spindle: 1.5 kw industrial air-cooled spindle (optional)

- Spindle speed: up to 24,000 rpm

- 5x Proximity switches for safety, zeroing and calibration

- Control: PC with Mach3

- Ball screw: On the Z-axis

- Ball screw drive: On the X, A and Y-axis

- Nema 23 motors

- Linear guide on all axes, HIWIN type

- Repeatability: ~ +/- 0.1-0.05 mm

- Backlash: ~ +/- 0.1-0.05 mm

- Voltage: 230V / 10 amp single phase

- Replaceable table with clamps

- CE marked

Dimensions for 1000×764mm Machine:

- Machine footprint: approx. (L) 1005 mm × (W) 925 mm (including motor covers)

- Work area: (L) 1000 mm × (W) 650 mm (material can extend beyond the bed)

- Maximum cutting area: (L) 720 mm × (W) 500 mm

- Clearance under Z-axis: 145 mm

Dimensions for 1000×1180mm Machine

- Machine footprint: approx. (L) 1005 mm × (W) 1170 mm (including motor covers)

- Work area: (L) 1000 mm × (W) 890 mm (material can extend beyond the bed)

- Maximum cutting area: (L) 720 mm × (W) 760 mm

- Clearance under Z-axis: 145 mm

Features (Mach3 only — all features can be configured in other software, but we only provide support for Mach3)

- 90-degree auto-calibration at startup

- 5 safety, homing, and calibration switches

- Probe functions (wiring required by user)

- Machine homing using proximity switches for extra accuracy

- Hastighet ca 6000-4000mm/min

- Cuts wood, plastic, and soft metals

- LED lighting under the X-axis (optional and pre-wired)

- Lightweight design, suitable for plastic and wooden floors

- Compatible with all Nema 23 motor controllers

- Support via email or our website

This is included (and options)

- Raw Avantic CE certified CNC machine

- Mach3 control software (Optional)

- Electronics box that can be unplugged for easy service

- Calibration plate to calibrate X, Y and Z axis, i.e. all axes.

- 65mm Air cooled spindle with inverter connected to other electronics (optional)

- 65mm Dust collector (optional)

- 65mm spindle mount (fits most edge routers and 1.5kw spindles)

- Keys for spindle (if you choose for spindle)

- ER11 collets 1-7mm (if you choose for spindle)

- 4x Clamps to hold down the workpiece (if you choose for consumable table)

- 3x cutters

- Support via phone or email

Note:

The machine base, regardless of size, uses 20×40 mm aluminum profiles. Combined with 12mm and 16 mm spoilboards, the total base height is approximately 70 mm. This is not strong enough for the machine to stand on its own — it must be placed on a flat and stable surface.

If desired, you can build a reinforced steel frame to allow the machine to stand independently.

Options (select options at the top of the page to see price)

Waste board

When ordering your Raw Creative machine, you have the option to add a Waste board, custom-designed to fit the machine’s construction.

The table consists of two layers – a wear surface and a base layer that locks the machine frame at a perfect 90-degree angle.

The top layer (the wear surface) can easily be replaced when it becomes worn.

Prefer to build your own table? No problem – watch the guide here:

👉 Build your own table – video

1.5kw spindle with Control Unit (VFD)

Choose to get a 1.5kw spindle with the ability to use 1-7mm inserts. Most often you cut with thin inserts such as 3-4mm for finer cuts and then 6mm to remove surface, so 1-7mm is usually enough. The spindle is connected to other electronics for automatic start and stop through the software.

All the videos below are on our previous model with HPL and aluminum instead of steel sheet. The machine is now made of heavy duty powder coated steel.

Repeatability and Backlash

Repeatability and backlash are often used by manufacturers to indicate machine accuracy — but these values can be misleading, especially when it comes to aluminum-framed machines. All aluminum frames have some degree of flex when under load.

Our machines have virtually zero backlash and excellent precision when moving without resistance (“in the air”), but as soon as you begin cutting material, there is inevitably some structural play. This applies to all aluminum-based machines in our price range.

We use as much steel as possible to counteract this and have designed an extremely rigid frame, but to stay realistic, we can only guarantee around ±0.1 mm for both repeatability and backlash.

Don’t rely solely on these numbers — real-world accuracy depends on the type of machine, material resistance, tooling, feed rate, and your settings. See the video below for a demonstration.

3D cutout