Product Description

Right now, the delivery time is slightly longer, about 3–6 weeks, due to high order intake.

If you want a chassis for the machine, it is available as a separate product.

Performance Where It Matters

Our machines are designed to strike the perfect balance between performance and budget. By cutting away non-essential extras while keeping all the key functions, we deliver a reliable and powerful CNC solution at a price more businesses can afford.

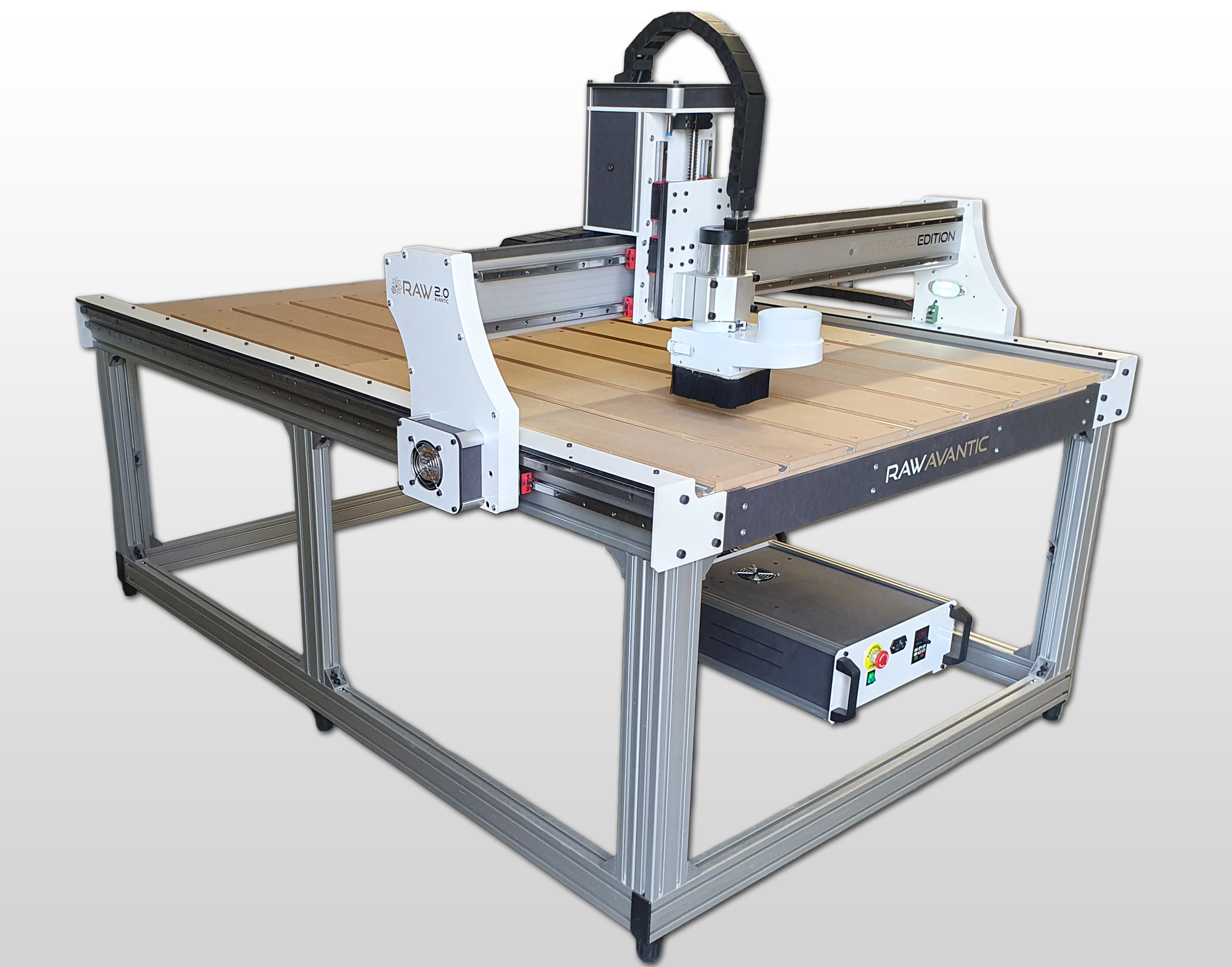

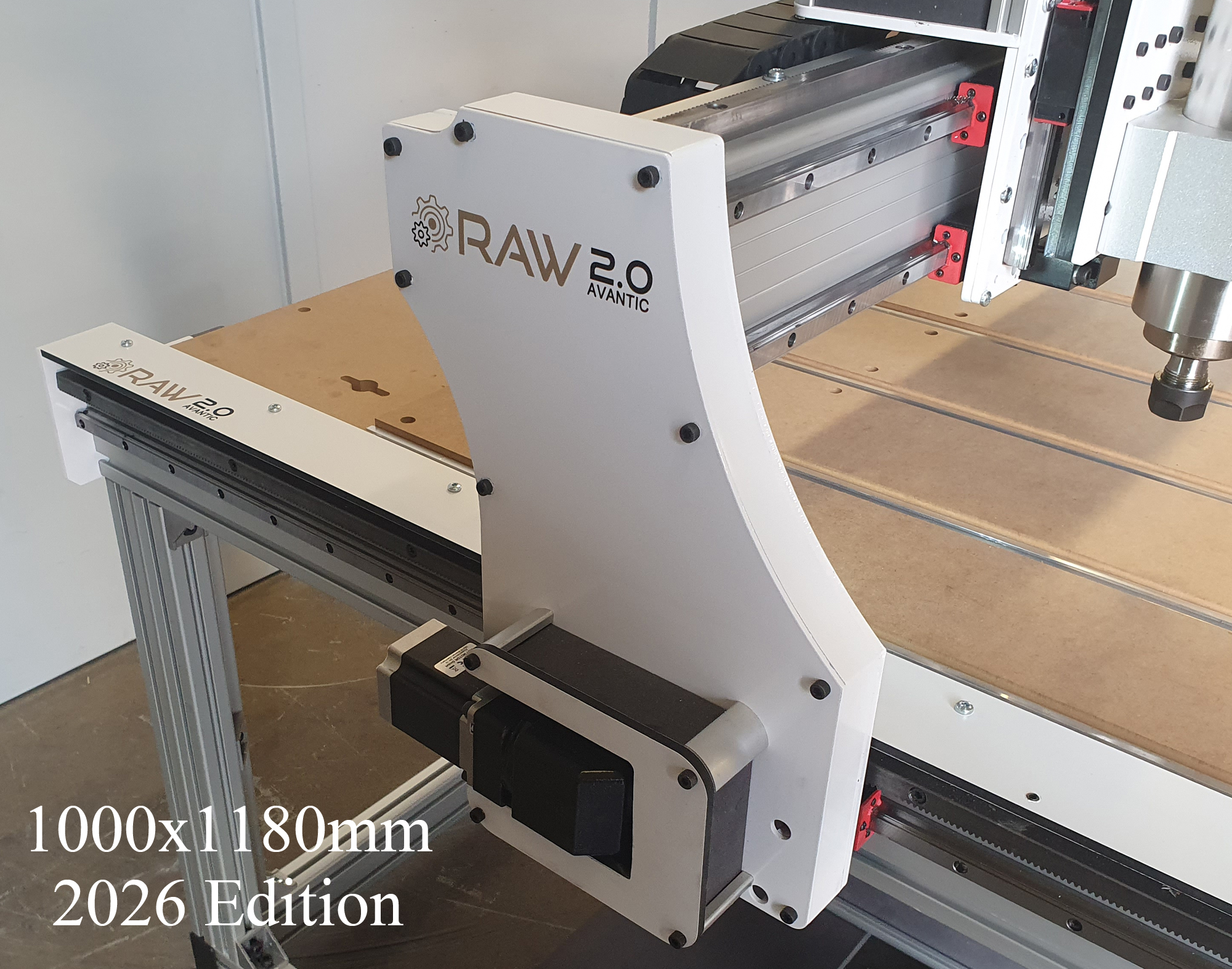

Raw Avantic Extended

Raw Extended is a more robust version of Raw Avantic, which means the machine flexes less. The plates are now steel instead of aluminium. The Z-axis assembly has been redesigned so all electronics can be hidden behind protection from dust and impacts.

The side motors are also enclosed and fully protected. The electronics enclosure has been reinforced. The side structure is stronger and more stable. The machine can be supplied with helical racks, gearboxes, and other accessories.

This is the closest we can get to a steel-built industrial machine. With this machine you can run series production in a professional environment with outstanding precision. Please note that the machine comes as a desktop version as shown in the picture, You can build a heavy-duty table for the machine (as shown), or purchase a chassis as a separate product. The chassis stands on adjustable feet.

The machine below is the same as this one but larger.

Describing the machine requires a lot of text so here is a summary, more advanced text below

- The machine is complete and you can start cutting with it straight away.

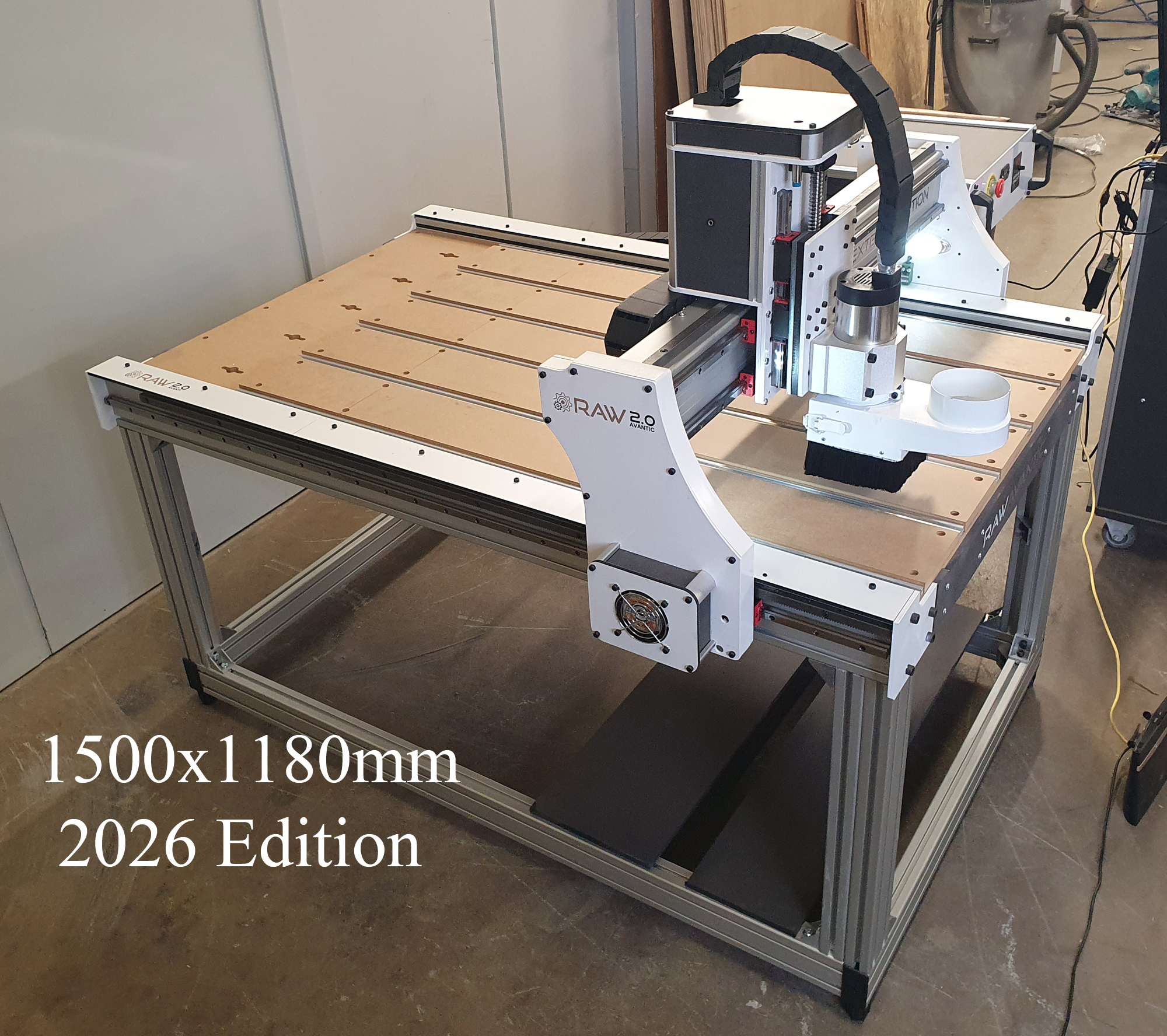

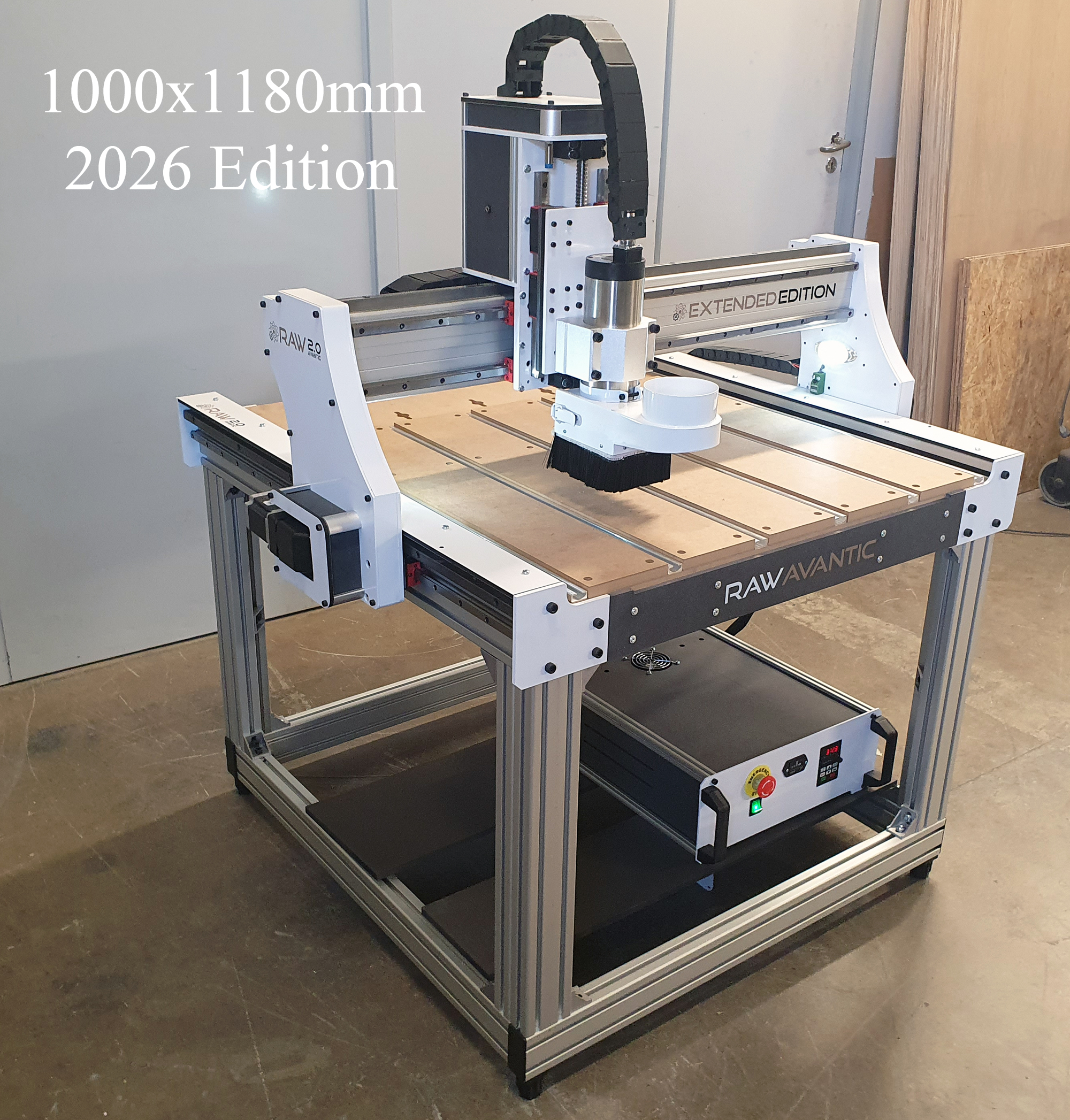

- The machine can be ordered in three different sizes, 1500x2000mm with cutting surface: (W)1220mm x (L)1710mm, 1180x1500mm with cutting surface: (W)750 x (L)1210 mm and 1180x1000mm with cutting surface: (W)750 x (L)720mm

- It is not difficult to operate the machine, once you have done it you will know. All the text below makes it look complicated but it is simple. see our instructional video at the bottom of the page.

- The machine is controlled with any Windows computer via USB port and a program called Mach3. If you do not already have it, you must select it in the drop menu above. The files you are going to cut are set in a so-called CAM program. Read more about the software below.

- You can draw simpler models in the CAM software we recommend, if you need more complex parts you can use any CAD program (drawing program) you want, the machine is compatible with most drawing programs on the market.

Options

There are many options for the machine. At the bottom of the page we will go through all the options for this machine.

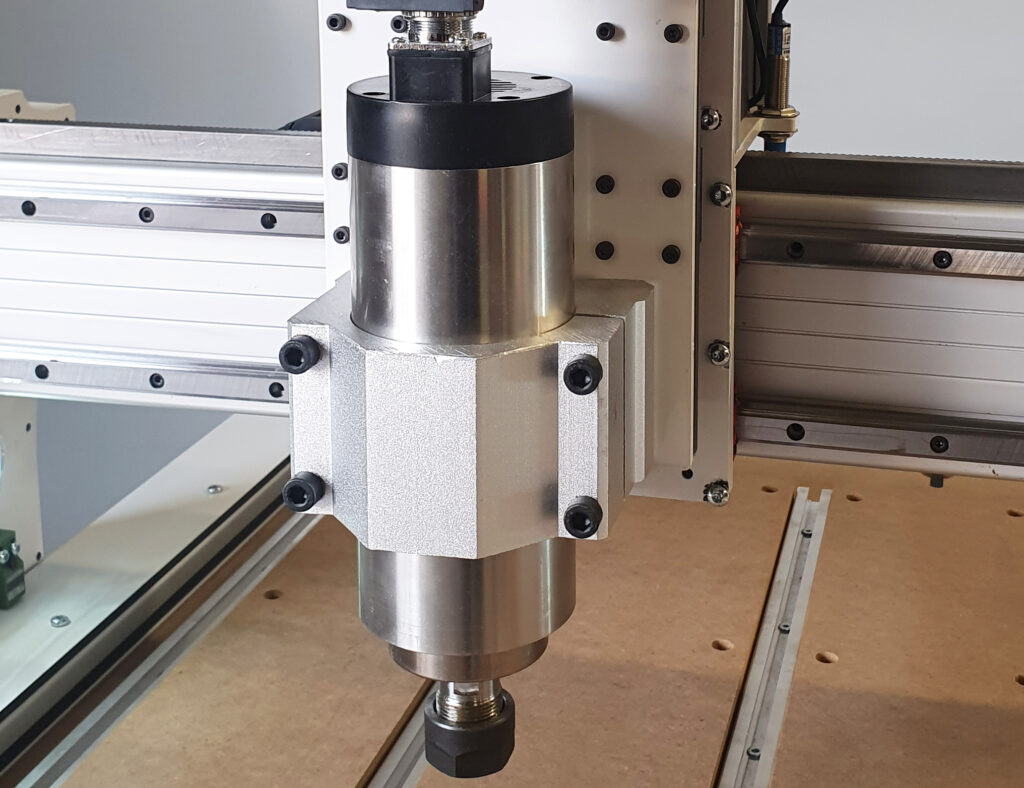

2.2kw spindle

Avantic Extended is delivered with a heavy-duty, air-cooled 2.2 kW spindle with an integrated inverter, wired into the rest of the electronics. These spindles are very powerful, quiet, and reliable. We use them ourselves and have done so for many years. With this spindle you can use cutters from 1–13 mm (ER20). We include a couple of end mills to get you started.

Protection and dust hood

All our machines are supplied with a protective shroud that efficiently captures dust and any chips.

Calibration

Avantic has 5 safety, homing and calibration switches for safety and precision. The switches are so-called Proximity switches that have no mechanical parts. Proximity switches are extremely accurate so that the machine can return to its “home” position with the best possible precision.

The safety switches ensure that the machine cannot go too far and stop the system and spindle as soon as the machine goes too far in any direction.

Precision

Precision is a balance between user and machine. It’s about how good your drawings are, spindle, speed and how fast you cut. At a normal speed of about 2-4000m / min the machine has the same accuracy as expensive industrial machines.

The machine is built to mainly cut wood, plastic and similar materials. You can cut aluminum but it requires experience regardless of which machine you use.

Is it difficult to work with a CNC machine?

No, it’s simple. Raw Avantic is one of the easiest machines to work with on the market. We have placed great emphasis on making the machines as easy to operate as possible. You do not need to have previous knowledge or education. The only difficult thing is to draw your parts, the rest is easy. Once you have cut your first piece, you will understand. Watch our videos on the website and YouTube to see how easy it is to work with a Raw Avantic machine

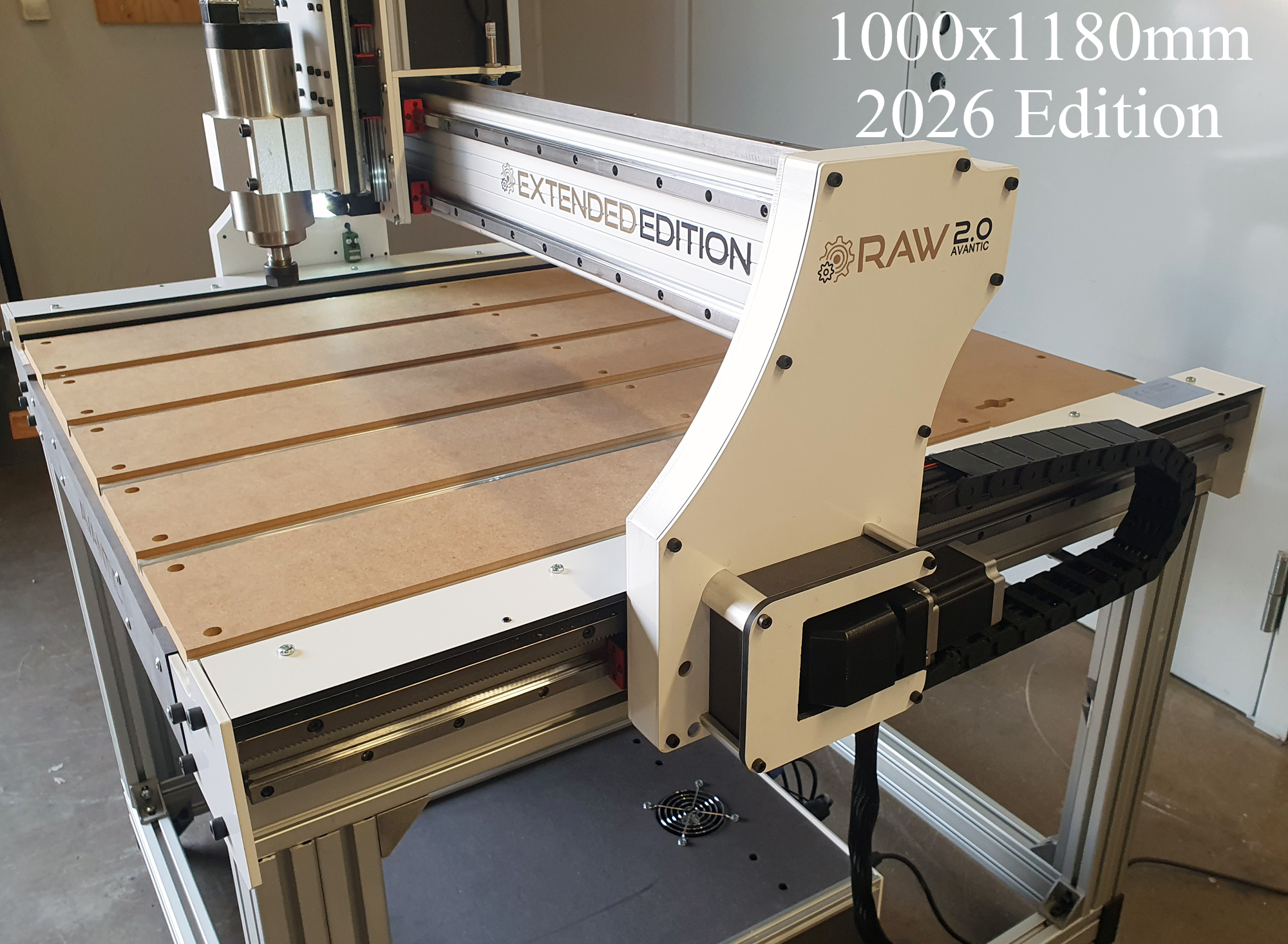

Linear guide rail

Avantic is supplied with guide rails and blocks of Hiwin type. Guide rails have an extreme precision that ensures that the shafts do not “play” and are preferable to other solutions.

Guide rails enable extreme speeds and precision. Expensive industrial machines run exclusively with guide rails and there is a good reason for that.

Each block can be lubricated individually with machine grease or spray grease that is sprayed directly onto the rails.

Consumption table (Waste board)

The consumable table is made of MDF and consists of two tables, a base table and a consumable table. You can easily cut out a new consumable table in MDF or other material after you have worn out the old one.

The rails are specially made to fit our clamps. The table is of the infinity type which means that you can run longer pieces than the table by pushing it forward between runs.

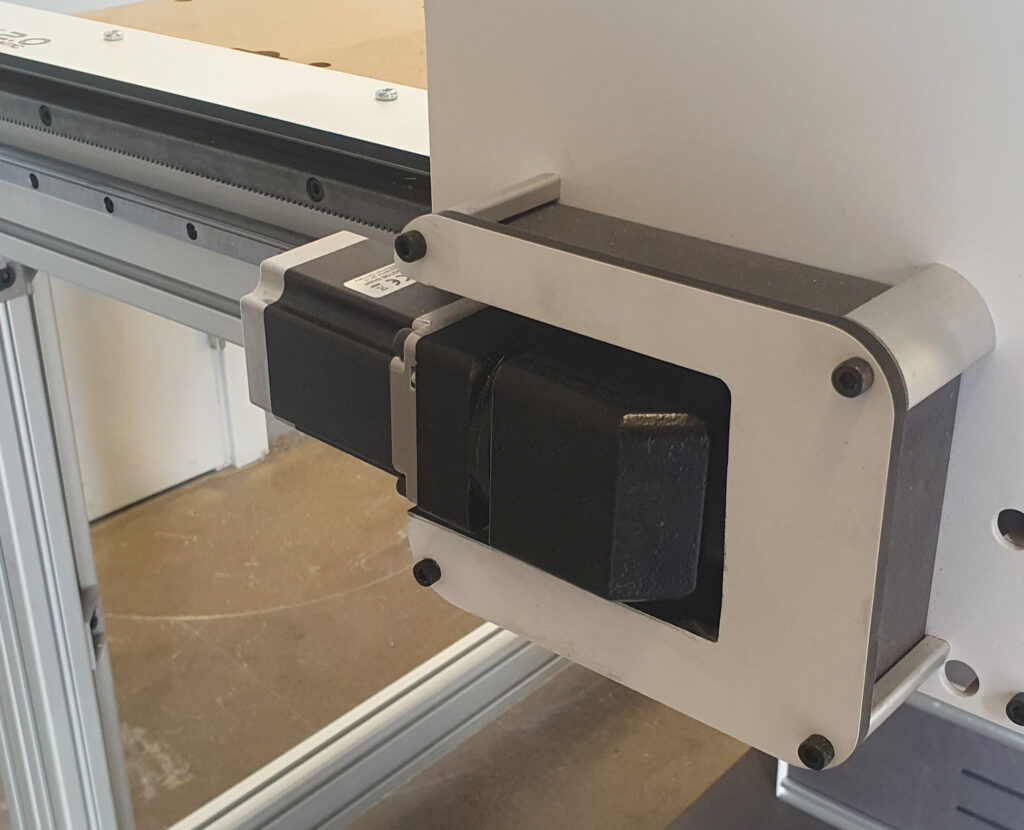

NEMA 23 motors

We have chosen the strongest 3A nema 23 motors on the market. The machine has a low weight and can run at unusually high speeds thanks to carefully selected gear dimensions.

The motors are so strong that a grown man can stand on the gantry while the machine cuts. The choice of parts is crucial for whether you need 3-phase or a regular 220 socket. We have scaled everything down so that 220 volts and 10 amps are enough.

How is the machine delivered?

We assemble the entire machine and then disassemble it for shipping. This means that the machine is delivered in larger parts to be able to be brought in through doors and gates. If you want it completely assembled, you must be responsible for shipping or pick up the machine on site. The machine is screwed together and then disassembled, there may be marks from screws.

Advantage of our desktop machines

We always try to keep the weight of our machines down. If you compare a larger Avantic that weighs about 150-200kg, a steel machine weighs up to 2 tons in the same dimensions.

A steel machine can only stand on concrete floors, while an Avantic can stand anywhere you want and can also be carried up or down stairs.

A steel machine requires a truck or crane truck that can unload 2 tons. To bring in a steel machine, you need large gates, while an Avantic can be moved with a pallet lift and through doors. If the machine is in the way, it can be moved. Our machines do not have the same mass as expensive industrial machines, but if you cut wood, plastic or aluminum, it is more than enough.

Beveled racks.

The machine comes with straight racks as standard. Straight racks work well but have a louder sound and more vibrations. The vibrations are only noticeable when you operate the machine with the arrow keys, when cutting the motors work in a different way and provide a smooth operation even with straight racks.

Beveled racks are more expensive but make the machine quiet and provide a very smooth operation and less backlash.

Both versions work well and the result of the cutting is almost the same, the big difference is the sound from the racks.

Gearboxes for X,Y and A axis

As standard, the gears are in direct drive against the rack, this works perfectly and the advantages are many. By having the gears in direct contact, we can increase the speed of the machine and eliminate any backlash and give very nice cutting results, see examples here: https://www.youtube.com/watch?v=jqUt81tqz6M

You can also choose to have the machine delivered with gearboxes. Choose gearboxes if you are unsure about direct drive as we recommend. Note that with gearboxes the machine will run much slower and about 10,000mm/min. (which is still fast). The machine will also have more play between the mechanical parts and give more “Backlash” than with direct drive. Gearboxes are expensive so we recommend that you first try without. Gearboxes can easily be mounted afterwards. We ourselves run exclusively with direct drive and have done so for over 10 years without any problems whatsoever, quite the opposite.

What can I cut with a Raw Avantic Extended?

Soft wood, hard wood, chipboard, MDF, plastic, aluminum, sign making, 3D cutting and engraving etc. All materials have different properties and require the right speed and end mill. But after a little practice, it’s easy.

Software

Cutting with a CNC machine requires 2-3 different software’s such as drawing, CAM (set up the files you drew) and Control software (to run the file). To control this machine we use Mach3. The CAM software we recommend is available in different versions and is called Vectric. the software also has an integrated drawing program for simpler models and you can get by with these two programs in the beginning. Read more about the CAM software below this text. If you outgrow the drawing part in the CAM, you can use more advanced drawing software’s such as Auto CAD or Fusion360 and others. If you are unsure how to do it and what software is needed, we will help you, just ask.

Mach3

Mach3 is the most used control software in the world, which means that there is more support and features for this software than any other. Mach3 looks outdated but we have updated it with our own UI to make it look more modern. The update is completely free and instructions can be found here: Update Mach3, see image to the right.

UCCNC, Linux or other control software

Avantic is compatible with most control software but we only have settings for Mach3. If you have decent knowledge of control programs, it is easy to set the machine to any option.

To set up the machine

After your machine is delivered, it must be set up with control software to be able to run. You can also choose to include a computer when purchasing. The computer is then completely installed, but you need to purchase a monitor, mouse and keyboard.

We have a guide for this at the top of the page “Configure your machine here” If you run into obstacles or feel you don’t have time, we can do it for you. Send the computer to us while you build your machine. The computer must be version WINDOWS 7-10. The computer does not need to have high performance as it is only supposed to control the machine. We recommend that you have a separate computer to control the machine. Alternatively, you buy a computer from us with everything already installed,

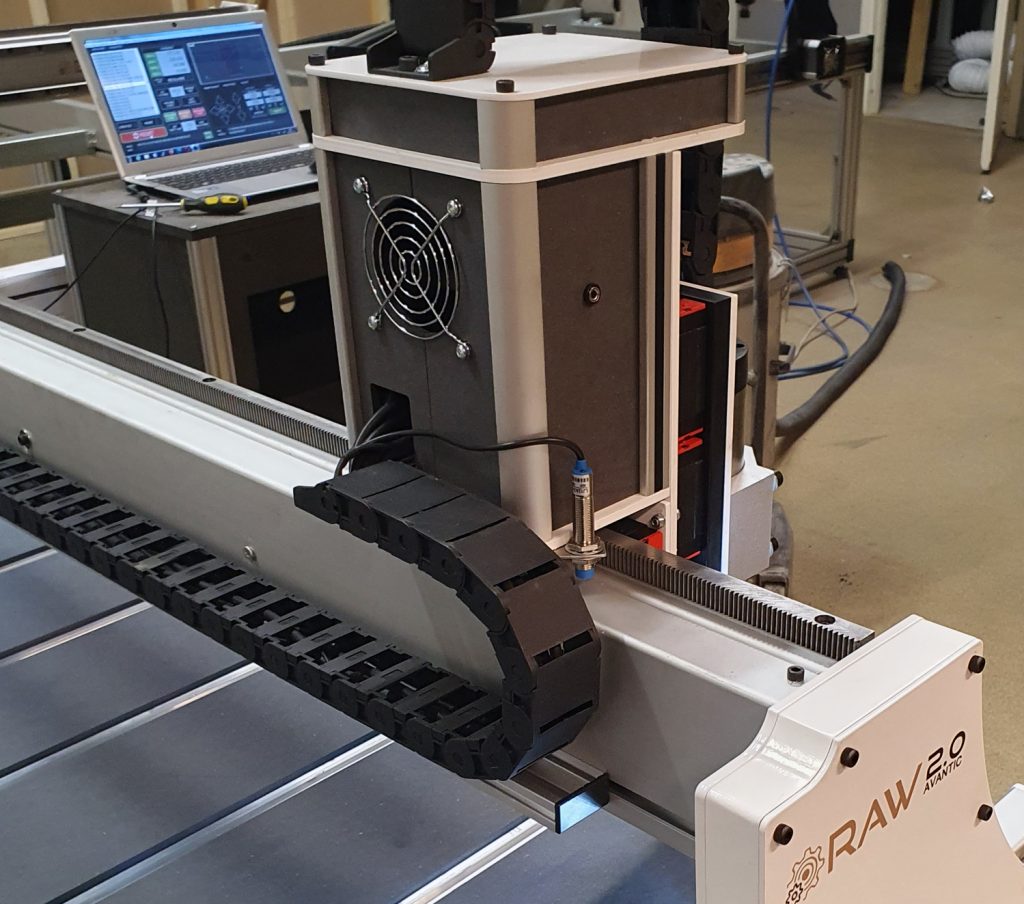

Modular design

Raw Avantic Extended is built with a well-thought-out modular construction, which makes service and repair both quick and easy. All key components are designed to be easily dismantled and sent to us when needed – without the need to transport the entire machine.

All electronics are collected in the X-axis, which can be quickly detached and sent in. Similarly, the Z-axis, motors, electrical box and other vital parts are also modularly designed, which means that we can carry out service or repair with minimal downtime for you.

With this solution, you get a machine that is both easy to maintain and cost-effective to own over time.

Built-in motors

All motors on an Avantic Extended are built-in and protected from shocks and dust. The motor covers are easy to remove for service or repair.

Rebuilt Z-axis

The Z axis of an Extended machine is built of steel and has protected electronics. The axle is removable for easier servicing if needed.

Stronger base

The base/consumption table is now about 4cm thicker than before and makes the whole machine much more stable. this is important if you are cutting in tougher materials such as Aluminum or steel.

Built by workers for workers

Raw Avantic is manufactured in Sweden and developed by us who previously worked as furniture carpenters. The machine came as an alternative to the expensive, heavy Asia machines that usually have a delivery time of 3-4 months and with questionable support. We always have personal support and guarantees.

Steel plates

Previously, all plates were made of aluminum. With this model, we are switching to steel plates which are much heavier and more stable. A heavier machine provides more stability and thus better cuts. The frame of the machine is laser welded with strong steel tubes to avoid “Flex” for tougher jobs.

The steel plates are laser cut and powder coated to withstand tougher work.

More powerful and smarter electric box

The electrical box is not built into the machine like many other machines in this price range. All connectors can be pulled out for possible service if necessary.

The machines are still adapted for standard sockets of 220 volts and 10 Amperes.

We have also reserved a place for a fifth axis that can be used for rotating axis etc.

We build the machines with other machines

We build our machines with state-of-the-art fiber lasers, CNC machines and laser welders. We cut the parts with fiber lasers and then powder coat them in house.

The frames are laser welded in jigs to ensure a calibrated and strong structural steel machine in strength and precision.

Some of our customers (Swedish companies)

Shipping

Shipping a CNC machine is expensive, due to its size and weight. The prize on our site is the actual cost and sometimes less. You can use your own shipping company but let us know beforehand. If you have the opportunity, you can pick up the machine from us in Sweden.

Due to high delivery costs for large machines this machine comes in larger parts that the user must assemble themselves. You have to assemble the table itself and attach the consumable table, the rest comes in large parts.

You will also find manuals and video instructions on our website. You can call us at any time with questions and for help with setting up your files. We guarantee help and will not leave you with unanswered questions.

Payment Terms

You can pay the full amount upfront or a deposit of at least 30% of the total price. The deposit secures material procurement and starts production. Lead time is calculated from the day we receive the deposit or full payment. Place your order as usual; if you prefer to pay only the 30% deposit now, email us and we’ll arrange it.

Tax

As a EU member you need to pay Swedish tax of 25% if you don’t own a valid company. If you own a valid company, you will need to enter your VAT number at checkout and the tax will not be added to the price. We will check with the registry to see that you have a valid company, if not we will have to charge you the tax even after delivery.

Specifications

- Color: Black, White

- Material: Steel sheet, HPL, Aluminum reinforced with steel

- Consumer table: Replaceable with rails

- Spindle: 2.2 kw industrial air-cooled spindle

- Spindle speed: up to 24,000 rpm

- LED lights under the X-axis

- 5x Proximity switches for safety, zeroing and calibration

- Control: PC with Mach3

- Ball screw: On the Z-axis

- Rack drive: On the X, A and Y-axis

- Beveled racks: X, A and Y-axis (optional)

- NEMA 23 stepper motors with or without gearbox

- Low weight and suitable for plastic and wooden floors

- Specially designed aluminum profiles

- Strong construction that allows for undercarriage

- Linear guide on all axes, HIWIN type

- Repeatability: +/- 0.1-0.05 mm

- Backlash: +/- 0.1-0.05 mm

- Voltage: 230V single phase

- Replaceable consumable table with clamps

- Aluminum table with adjustable feet as an option

- Support by phone and email

- CE certified

Size of 1500x2000mm machine

- Machine footprint approx. (W) 1500 x 2000mm

- Working area: (W) 1280mm x (L) 2000mm (the board can protrude, for example an entire MDF board)

- Max cut-out: (W) 1220mm x (L) 1710mm

- Height below Z-axis: ~150mm

Size of 1180x1500mm machine

- Machine footprint (W) 1180x (L) 1500mm

- Working area: (W) 890x (L) 1500mm

- Max cut-out: (W) 750 x (L) 1210mm

- Height below Z-axis: ~150mm

Size of 1180x1000mm machine

- Machine footprint (W) 1180x (L) 1000mm

- Working area: (W) 890x (L) 1000mm

- Max cut-out: (W) 750 x (L) 720mm

- Height below Z-axis: ~150mm

Functions

- 90-degree calibration at start-up

- 6 safety, home and calibration switches

- Calibration functions to calibrate all directions, left, right, up, down and height

- “Homing” of machine with Proximity switch for extra accuracy

- Speeds up to 25000mm/min (10000mm/min with gearboxes)

- Cut in wood, plastic and soft metal

- LED lights below the X-axis

- Light weight and suitable for plastic and wooden floors

- Support by phone and email

This is included

- Raw Avantic CE certified CNC machine

- UC100 module

- Mach3 software (optional)

- Electronic box that can be unplugged for easy service

- Calibration plate to calibrate X, Y and Z axis, ie all axes.

- 80mm Air-cooled spindle with inverter connected to CNC electronics

- 80mm Dust collector

- Keys for spindle 22 and 30mm

- 13 ER20 collets for spindle 1-13mm

- 4x Clamps to hold down the workpiece

- 3x end mills to get you started

- Instruction manual for CNC machine

- instructional video and access to dedicated website for the machine

- Support by phone or email

Optional (select optional at the top of the page to see price)

Mach3

Mach3 is control software used to operate the machine. There are several control programs such as UCCNC, Mach4, Linux, and others. We have chosen Mach3 because it is the most widely used control software in the world, which means there are countless features and resources available—often free to download. The machine is compatible with almost all control systems that are not Arduino-based, so you can switch control software whenever you like. Note that we only provide settings for Mach3; if you have some experience, it’s straightforward to configure the machine for any other control software. If you include Mach3 with your order, you also receive our updated user interface (described above).

Preconfigured PC

You can choose to include a preconfigured computer so you can get started right away. The computer is new and a mini PC with the following specifications: fanless Intel N3350 mini PC, Windows 10 Pro, 6 GB RAM, 64 GB storage, Wi-Fi, HDMI & VGA dual-screen support, USB 3.0, and M.2 2280 SSD support.

Please note: you will need to provide a monitor, mouse, and keyboard. The PC comes with everything installed to get you up and running immediately. The control software is a demo version by default, but you can add a Mach3 licence and we will install it for you.

Helical Racks and Pinions

The machine is supplied with straight racks as standard. Straight racks work well but produce more noise and vibration. The vibration is primarily noticeable when jogging the machine with the arrow keys; during cutting the motors operate differently and the motion is smooth even with straight racks. Helical racks are more expensive, but they make the machine much quieter, provide very smooth motion, and reduce backlash. Both options work well and cutting results are nearly the same—the main difference is the noise level from the rack and pinion.

Gearboxes for X, Y and A Motor

By default, the pinions drive the racks directly. This works excellently and offers several advantages: higher top speed and minimal backlash for very clean cutting results (see example: https://www.youtube.com/watch?v=jqUt81tqz6M).

You can also choose to have the machine delivered with gearboxes. Choose gearboxes if you are unsure about direct drive as we recommend. Note that with gearboxes the machine will run much slower and about 10,000mm/min. (which is still fast). The machine will also have more play between the mechanical parts and give more “Backlash” than with direct drive. Gearboxes are expensive so we recommend that you first try without. Gearboxes can easily be mounted afterwards. We ourselves run exclusively with direct drive and have done so for almost 20 years without any problems whatsoever, quite the opposite.

Spoilboard (Waste Board)

Choose between standard MDF or a through-dyed, moisture-resistant variant. Select the moisture-resistant board if the machine will be in an environment with larger temperature variations, such as an unheated garage.

Please note that the instructions and video below are for an older version of the Avantic (2022 version). The machines today look and are slightly different but the instructions are the same. We are working on new videos for the Extended model.