Product Description

Available end of January 2026

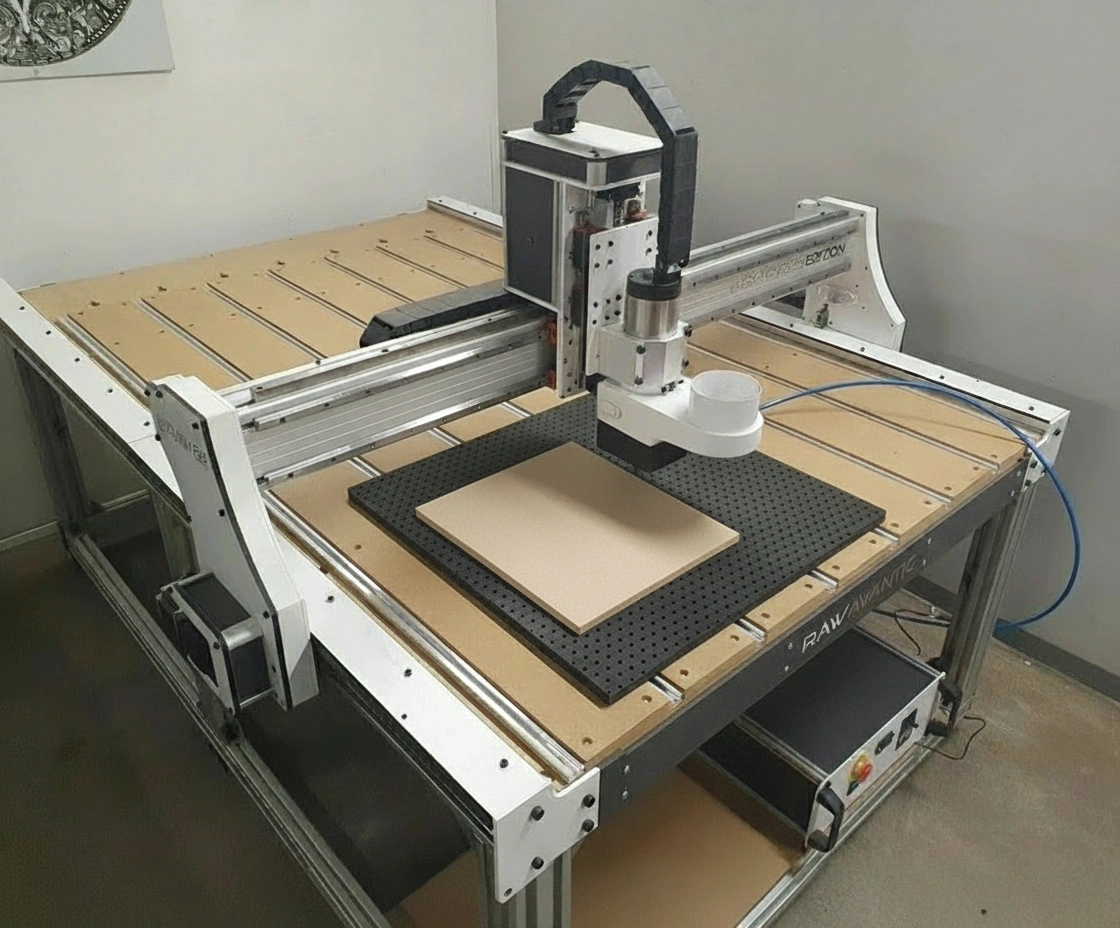

Images and additional information coming soon.

Perforated Vacuum Gasket for CNC – Designed for Precision and Flexibility

RawVac™ Gasket is used to create a sealed vacuum surface on CNC tables where the workpiece is held in place by negative pressure instead of mechanical clamps. By placing the gasket sheet between the vacuum table and the workpiece, the vacuum is evenly distributed across the surface, keeping the material stable during machining and enabling through-cutting without excessive loss of vacuum force that could cause small parts to come loose.

RawVac Gasket is developed for CNC applications where flexibility, adaptability, and stable vacuum hold-down are critical. The product is based on the same fundamental principle as traditional vacuum gaskets creating a sealed interface between the vacuum table and the workpiece but is designed with real-world use of smaller CNC machines, hobby users, and workshop environments in mind. The material we chose for the RawVac Gasket is more expensive, denser and more durable than other options on the market, despite this, the RawVac Gasket is cheaper than others.

Use and Through-Cutting

In CNC machining, RawVac Gasket is intended to be used as a consumable surface. Under normal operation, the cutting tool should not cut completely through the gasket sheet, but only partially into the material above it. This maintains vacuum sealing while keeping the workpiece securely held throughout the machining process.

When the gasket sheet becomes worn over time, it can easily be replaced, making RawVac Gasket a practical and cost-effective solution for everyday CNC use.

Self-Adhesive and Modular

RawVac Gasket is self-adhesive and is easily mounted directly onto a spoilboard. It can be cut to the desired size and combined with multiple sheets to build vacuum surfaces of the required dimensions.

The modular design makes it possible to:

- Adapt the gasket surface to different machines

- Build larger vacuum areas step by step

- Replace only the sections that wear out

Every CNC table is different—this is why RawVac Gasket is designed to be flexible and easy to adapt.

Developed Through Practical Testing

During development, various materials, perforation patterns, and formats were tested to find a solution that performs better when machining:

- Small parts

- Through-cutting into a spoilboard

- Varying materials and workpiece sizes

The result is a gasket that provides more predictable vacuum distribution and is easier to adapt to different machines and work surfaces.

Denser Hole Pattern for Better Control

RawVac Gasket features a denser hole pattern than those commonly used in industrial vacuum systems. Practical CNC testing shows that this provides:

- Improved stability for small parts

- More active vacuum points across the surface

- More forgiving hold-down when the workpiece does not cover large continuous areas

This is especially useful in hobby and workshop environments where flexibility is more important than maximum airflow per individual hole.

Straight Hole Grid – Optimized for CNC

The holes are arranged in a straight grid pattern, making the gasket sheet:

- Easy to cut accurately

- Simple to tile and combine in multiple sections

- Predictable in both X and Y directions

The straight pattern is intentionally chosen to align with how CNC users think and work with coordinates, clamping, and vacuum surface layouts.

Flexible Sheet Format

RawVac Gasket is supplied in a 500 × 600 mm sheet format. This size is chosen to:

- Minimize waste

- Simplify adaptation to different table sizes

- Make it easy to build larger vacuum surfaces by combining multiple sheets

Because no two CNC tables are the same, flexibility is more important than fixed standard dimensions.

Material Selection – Balance Between Sealing and Friction

The material is selected to provide a good balance between:

- Effective sealing against the vacuum table

- Sufficient friction against the workpiece

- Low weight and easy handling

RawVac Gasket is a consumable product designed to be easy to replace and adapt as needed.

Summary

RawVac Gasket performs the same fundamental task as traditional vacuum gaskets—but it is developed differently. With a denser hole pattern, straight grid layout, and a more flexible format, it offers improved control and adaptability for practical CNC use.