Product Description

Available end of January 2026, Pictures and more information coming soon!

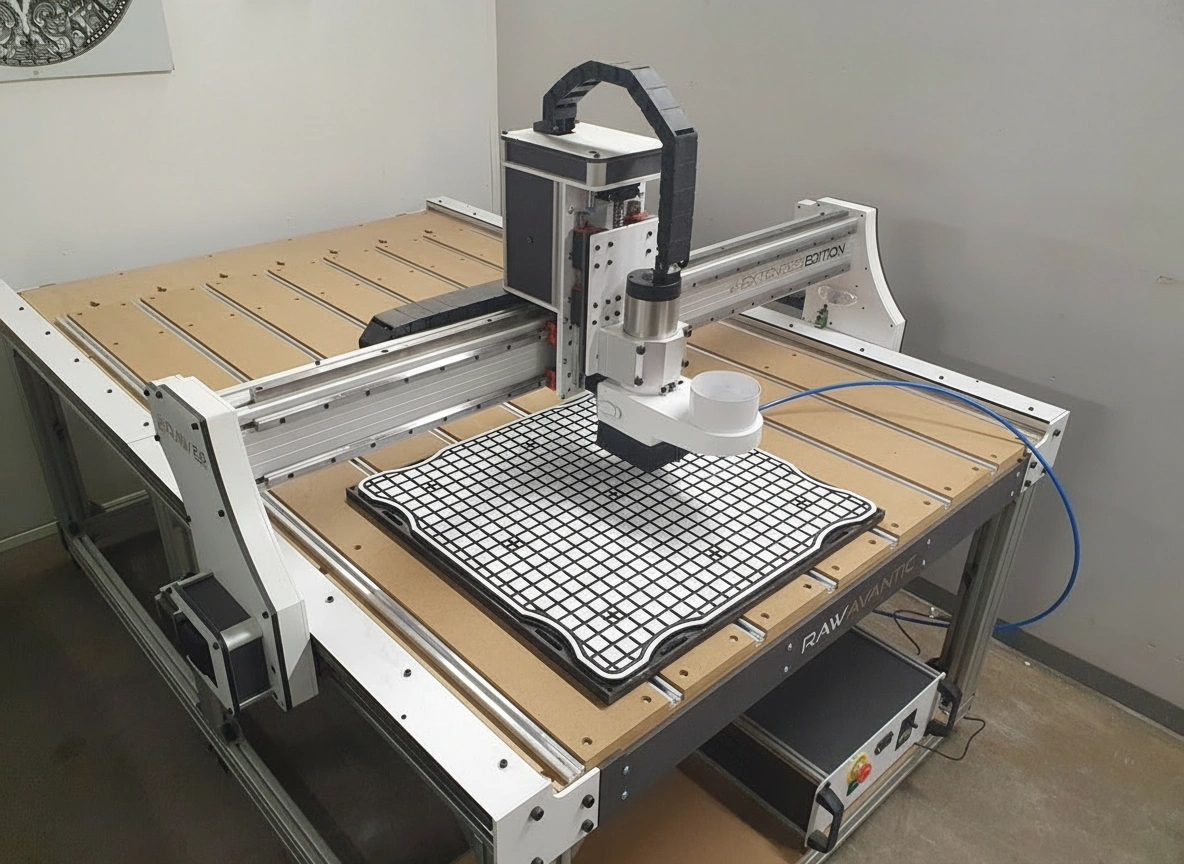

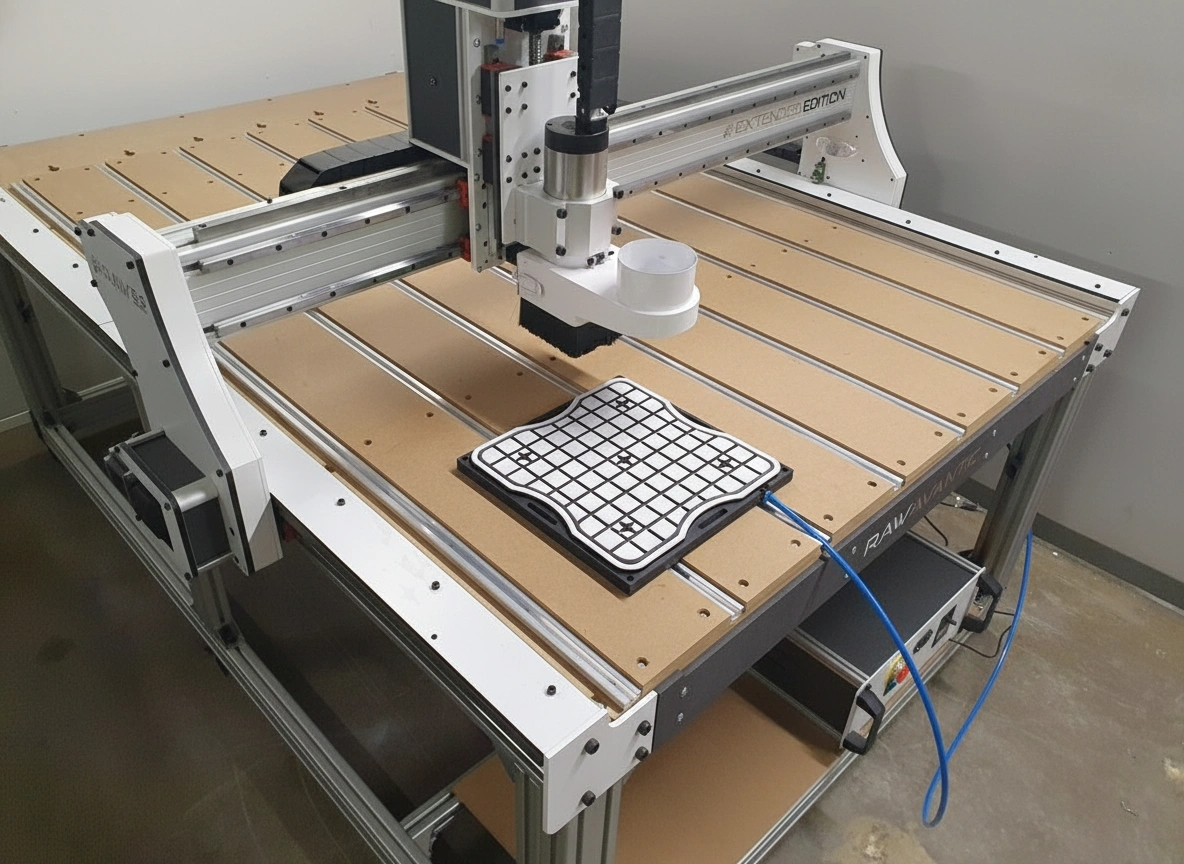

RawVac™ are vacuum tables developed to provide fast, safe and flexible clamping on CNC machines – without the need for clamps or screw fixtures. The tables have a size of approximately 300x300mm, 600 × 530mm and 530x1100mm and can be easily placed on top of an existing CNC table, making them ideal for both prototyping and production.

Thanks to a well-thought-out channel and hole pattern, the vacuum is distributed evenly over the entire surface, which provides a stable grip even on smaller or irregular workpieces. Clamping time is minimized – place the part, turn on the vacuum and start processing immediately.

Modular System with Zone Control

Multiple vacuum tables can be connected together and controlled via a manual control unit, allowing the vacuum distribution to be regulated between different tables or zones. This provides high flexibility and makes the system scalable according to machine size, workpieces, and workflow.

Zone Division and Flexible Vacuum Control

Each RawVac vacuum table is divided into multiple vacuum zones, allowing the holding force to be adapted to the size and shape of the workpiece. Zones that are not in use can easily be sealed with the supplied rubber plugs, concentrating the vacuum to the active surface area.

For additional flexibility, sealing tape is also included. This allows users to create custom zones or patterns directly on the table surface. By placing the sealing tape where the vacuum should be limited, clamping can be quickly adapted to the specific workpiece being machined.

This makes the vacuum table particularly suitable for:

- Small workpieces

- Irregular shapes

- Fixture work and contour cutting

- Series production with recurring geometries

The zone system improves vacuum efficiency, reduces air leakage, and provides more stable clamping—even when only part of the table surface is used.

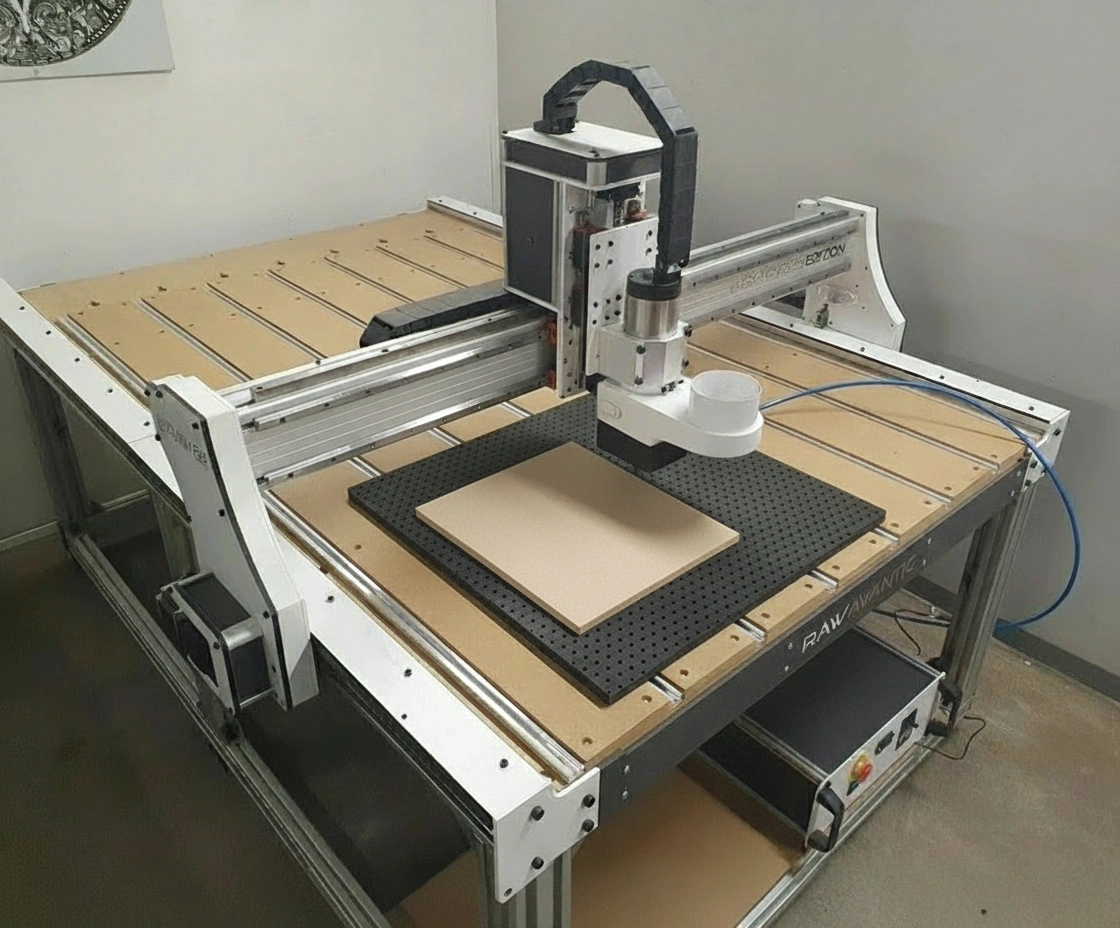

Through-Cutting with Spoilboard (MDF)

The vacuum tables are designed for through-cutting by using an MDF spoilboard. MDF is a porous material that allows air to pass through in a controlled manner. When the vacuum pump creates negative pressure, air is drawn through the spoilboard, allowing the vacuum to act on the workpiece above it.

Atmospheric pressure then presses the workpiece firmly against the spoilboard, ensuring secure hold-down even when the tool cuts completely through the material. This enables:

- Contour cutting and part cut-outs

- Fast series production

- Machining without clamps that interfere with tool paths

For improved holding performance, the vacuum table can be used together with RawVac Gasket, placed on top of the spoilboard. The gasket sheet helps reduce air leakage, improve vacuum distribution, and makes clamping more forgiving when machining small details or when the workpiece does not cover the entire surface.

The spoilboard can easily be resurfaced and replaced when worn, and the gasket sheet is a consumable that can be replaced as needed. This makes the solution both practical and cost-effective over time.

Benefits

- Fast and easy clamping

- No risk of collision with clamps

- Even holding force across the entire surface

- Improved vacuum sealing with gasket (optional)

- Modular and scalable system

- Suitable for both fixture work and through-cutting

Our vacuum tables are a flexible solution for users who want to work efficiently, repeatably, and professionally with CNC machining.

Included

- RawVac vacuum table in selected size

- 2 m hose, fittings, push-to-connect connectors for vacuum pump connection

- 3 m sealing tape for zone division

- Rubber plugs for zone sealing

- 1 × RawVac Gasket (self-adhesive, perforated) – included at no extra cost

Vacuum Pumps – Choosing the Right Capacity for Your Vacuum Table

It is possible to use basic vacuum pumps for CNC work, but in practice they are often too weak for vacuum tables—especially during through-cutting, in the presence of leakage, or when only part of the table surface is used. Many simpler pumps are also oil-lubricated, which means higher maintenance, risk of oil mist, and reduced suitability for workshop environments.

The vacuum pumps we offer are specifically designed for vacuum tables and CNC machining. They are engineered to deliver higher airflow, handle controlled leakage, and operate continuously—completely oil-free.

We offer three different vacuum pumps, matched to our vacuum tables and various CNC applications. The main differences between the pumps are airflow (CFM) and their ability to handle:

- System leakage

- Through-cutting with spoilboards

- Small workpieces and zone-based clamping

Choosing the correct pump capacity results in more stable clamping, better repeatability, and a more user-friendly vacuum system.

🔹 5 CFM – Compact and Efficient

Suitable for:

- Small workpieces

- Vacuum plates and fixtures with good sealing

- Precision work where low noise and compact size are important

Advantages:

- Small footprint and easy placement

- Low energy consumption

- Excellent holding force with well-sealed setups

🔹 9 CFM – Balanced All-Round Pump

Suitable for:

- Our standard vacuum tables

- Most CNC jobs using MDF spoilboards

- Through-cutting with moderate leakage

Advantages:

- Good balance between vacuum level and airflow

- Handles both fixture work and through-cutting

- Popular choice for both hobbyists and professionals

🔹 17 CFM – For Higher Demands

Suitable for:

- Larger workpieces

- Multiple vacuum tables connected simultaneously

- More demanding through-cutting and higher leakage levels

Advantages:

- Higher airflow maintains stable vacuum during through-cutting

- Better margin when machining porous materials

- Suitable for production environments and continuous operation

How to Choose the Right Pump

- Tight fixtures / vacuum plates: 5–9 CFM is usually sufficient

- Spoilboard and through-cutting: 9–17 CFM provides better stability

- Multiple tables or larger surfaces: 17 CFM recommended

All our pumps are selected to work optimally with our vacuum tables and are delivered ready for installation.

How Vacuum Hold-Down Works

A vacuum table does not hold the workpiece by “suction” in the traditional sense.

Instead, negative pressure is created between the table and the workpiece by removing air using a vacuum pump. As the pressure beneath the workpiece is reduced, atmospheric pressure above presses the material down against the table.

Designing a vacuum table that performs efficiently in real-world applications is not trivial. Even small leaks in materials, channels, or connections can quickly reduce vacuum levels and holding force. The internal channel structure, surface finish, and sealing of the table are therefore critical.

Our vacuum tables are developed with a strong focus on minimizing leakage and ensuring even vacuum distribution, resulting in stable and predictable clamping—even during demanding machining operations.

At a measured vacuum level of −0.8 bar, the pressure difference corresponds to a downward holding force of up to approximately 2.5 tons, evenly distributed across the entire table surface under well-sealed conditions. This provides secure clamping suitable for both milling and through-cutting operations.

Vacuum level can easily be monitored using a vacuum gauge, giving the user immediate feedback on clamping effectiveness and system sealing.

(Stated holding force is theoretical and based on pressure differential under sealed conditions. Actual holding force depends on material porosity, sealing, spoilboard condition, leakage, and selected vacuum pump.)

The product is CE-marked and developed in accordance with applicable EU requirements for safe and proper use in professional environments.